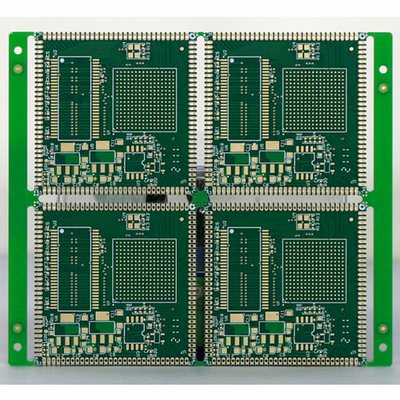

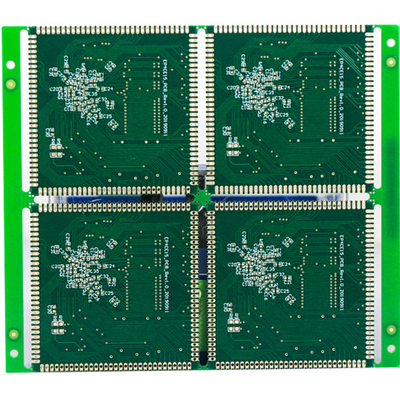

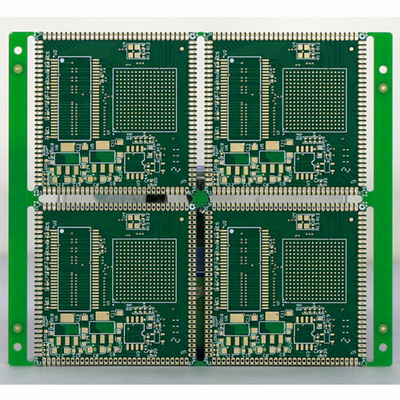

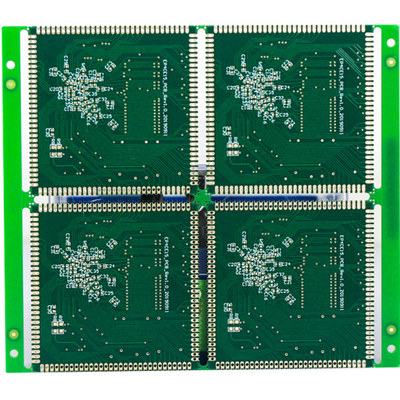

2.0mm Green Solder Mask Hdi Pcb Design 1.5oz 4 Layer Immersion Gold 3u

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| PCB Name | 4L 2+N+2 HDI PCB | Marterial | FR-4, S1000-2M |

|---|---|---|---|

| Board Layer | 4L | Board Thickness | 2.0mm |

| Finished Copper Weight Outer | 1.5oz | Internal Copper Weight Inner | 1oz |

| Solder Mask | Green Solder Mask | Smallest Hole Size | 0.1mm |

| High Light | 1.5oz Hdi Pcb Design,2.0mm 1.5oz Hdi Pcb Design,1.5oz interconnect pcb |

||

2.0mm Green Solder Mask Hdi Pcb Design 1.5oz 4 Layer Immersion Gold 3u

HDI PCB Board PCB Board Fabrication PCB Board Manufacturing Electronic PCB Board Green PCB Board

4L 2+N+2 HDI PCB

HDI PCB are abbreviation of high density interconnect printed circuit boards, they are characterized by finer lines, closer spaces, and more dense wiring.

For HDI boards own higher circuit density than traditional circuit boards, its designs can include smaller through holes and capture pads, and also higher connection pad density. They are widely used to reduce the weight and overall dimensions of products, as well as to enhance the electrical performance of the device.

HDI boards are applied to wide range of industries, like digital devices, smartphones and tablets, automobiles, aircraft and other vehicles products.

HDI Board Stack-up:

1+N+1 with laser microvia and mechanical buried core via. The “1” represents “build-up” or sequential lamination on each side of the core.

i+N+i (i>=2) PCBs contain 2 or more “build-up” of high-density interconnect layers. Microvias on different layers can be staggered or stacked. Copper filled stacked microvia structures are commonly seen in challenging designs.

HSX products cover 1~32L FR-4 PCB, IMS PCB,HDI Boards, high frequency PTFE boards and Rigid-flex boards etc. It provides flexible quick turn production services (12 hours to72 hours), as well as small volume to big volume PCB manufacturing. Products are widely used in high-tech fields such as communications, power supplies, computer networks, digital products, industrial control, science and education, medical devices, and aerospace. HSX owns high-educated and experienced team and advanced production equipment.

| PCB Layer | 4L 2+N+2 | PCB material | FR4 S1000-2M |

| Copper thickness | 1.5/1/1/1.5oz finished | PCB thickness | 2.0MM |

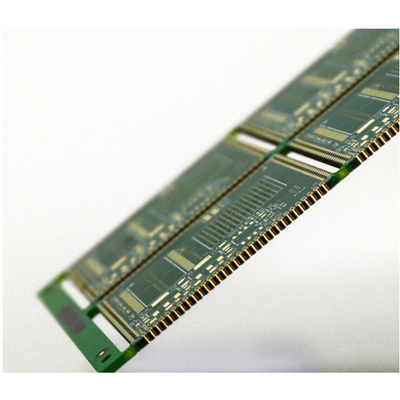

| Min. hole size | 0.1mm | Min.PCB track/gap: | 3mil |

| PCB solder mask | Green | PCB silkscreen | White |

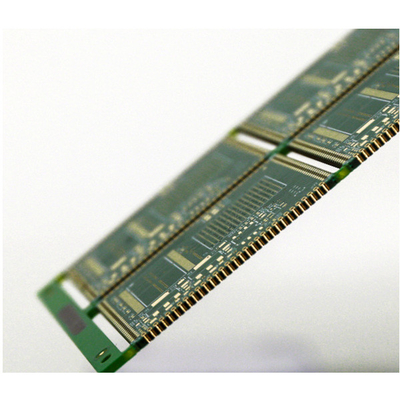

| PCB surface finished | Immersion Gold 3u | PCB outline | Routing/V-CUT |

| Application | Industrial control product | ||

| Special requirement: | 0.25mm BGA/FR-4+PI | ||

![]()

![]()

FAQ:

Q1:Are you a factory or trade company?

A: Yes, we are the factory, we have independent quick turn prototype PCB manufacturing & big volume PCB production lines.

Q2:What kind of PCB file format can you accept for production?

A: Gerber, PROTEL 99SE, PROTEL DXP, POWER PCB, CAM350, ODB+(.TGZ)

Q3:Are my PCB files safe when I submit them to you for manufacturing?

A: We respect customer's copyright and will never manufacture PCB for someone else with your files unless we receive written permission from your side, nor we'll share these files with any other 3rd parties. And we could sign NDA with client if necessary.

Q4:If we have no PCB file/Gerber file, only have the PCB sample,can you produce it for me?

A: Yes,we could help you to clone the PCB. Just send the sample PCB to us, we could clone the PCB design and work out it.

Q5:What is your standard lead time for PCB?

A: Sample/prototype(less than 3sqm):

1-2 Layers: 3 to 5working days (fastest 24hours for quick turn services)

4-8 Layers: 7~12 working days (fastest 48hours for quick turn services)

Mass production (less than 200sqm):

1-2 Layers:7 to 12 working days

4-8 Layers:10 to 15 working days